Linoleum for a nursery

Among the many floor coverings you can find a fairly suitable option that meets the requirements for facing the children's room. Consider linoleum - as one of the types of laying the floor in the nursery.

Characteristics of natural linoleum

Of the features of this flooring stand out both positive and negative qualities.

Advantages of such a floor surface:

- Environmentally friendly coating. Ingredients: jute, flax, cork and rubber;

- Hypoallergenic;

- Pleasant for perception;

- Ability to experiment. When buying a coating in the form of a tile or panels, you can make an original design sketch, while combining multi-colored elements;

- Wear resistance;

- Excellent resistance to temperature extremes;

- Resistance to mechanical stress;

- Antibacterial;

- Anti-static;

- Long service life;

- Color fastness;

- The possibility of laying a warm floor (for some models).

Minuses:

- High price. Compared with synthetic materials, the price of natural linoleum is significantly higher: 2-2.5 times;

- Few design options and color shades;

- Bent natural linoleum breaks down;

- Transportation requires extra effort;

- Difficult installation;

- Fixation is carried out only by the natural adhesive composition;

- Thin material easily deteriorates due to sharp objects, even an ordinary pencil can easily tear the flooring.

Varieties of linoleum

In addition to the natural fiber coating, manufacturers also produce some synthetic products. They can be divided into several groups.

In composition:

- Polyvinyl chloride (PVC) linoleum. It is made in three varieties: on fabric, foamed and insulating nonwoven fabric. This product is divided into layers: it happens with one layer or with several. It has an unpleasant smell and great shrinkage.

- Rubber the product or its second name is relin. The coating of this material is two-layer, the base is bitumen or used crushed rubber. The outer layer Relina incorporates rubber and pigmented filler. Differs in resistance to humidity and good plastic features.

- Kollokeilinovy linoleum. The second name of such a product is “nitrocellulose linoleum”. This thin coating has no base. It is characterized by fast flammability, excellent elastic characteristics, moisture resistance and chic shine.

- Hyphthalic or alkyd coating. Basis - woven component. It has the best sound and thermal insulation properties, but it is very fragile.

To destination and wear resistance:

- For everyday functions. Such material is intended for use in residential buildings. It is made on the foamed component or polyester. Thickness - only 4 mm. It has a lot of design solutions. The features are: ease of installation, simplicity of operation, softness and quick wear (with heavy loads and frequent walking on it).

- Semi-commercial option. Often it is used in residential buildings, hotels and offices. Differs in rather big service life due to an additional sheeting in 0,7mm. The structure of the material is similar to household linoleum.

- Commercial type. Used for places with a great stay of people. The basis is polyvinyl chloride.Durability is achieved by durable outer layer. Appearance over time remains the same.

According to the structure:

- Homogenous type. The structure of the coating is based on a mixture of PVC and pigments of the same type. The pattern of this product is pierced through the entire surface. It is used in places with a great stay of people due to good properties for wear resistance.

- Heterogeneous option. Multilayer material, can consist of up to 6 layers of PVC. The base is fiberglass. In the form of a footboard, one of three components is commonly used: fabric, nonwoven fiber, or foam.

- Groundless coating. Cheap and with a short life option linoleum. Differs in fine structure: from 1.5 to 3 mm. When installing such a coating, it is necessary that the surface be perfectly flat.

- Basic type. It can go on almost all grounds due to its elastic characteristics. One of three variations is used as a substrate: fabric, non-fabric or heat-insulating material.

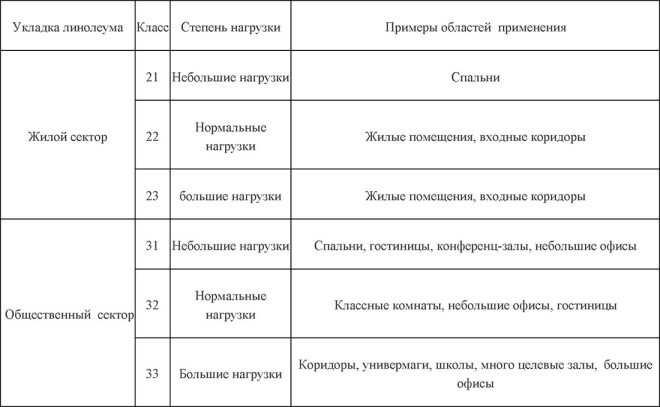

Appointment and load

Due to the marking, each batch of linoleum has a certain criterion by which it is possible to judge its purpose, and which material the material can withstand.

The first numerical designation indicates its purpose:

- 1 - suitable for rooms with low traffic.

- 2 - for residential premises.

- 3 - for offices.

- 4 - for industrial premises.

The second digital from 1 to 4 designation indicates the load withstand linoleum, where 1 - for the minimum, 4 - for the maximum.

How to choose for different ages

When buying it is worth paying attention not only to the color design of the floor surface, but also to the thickness of the coating, and also to take into account the age of the child.

From 1 to 3 years

For children from 1 to 3 years is not worth buying material with bright colors. It is better to buy linoleum of calm tones - this helps to normalize the psyche of the child, and the brightness of the colors is better left for toys. Thermal insulation of the floor should be achieved due to the thickness of the coating, so when choosing, pay attention to the surface with a rating of at least 3 mm. Additionally, there should be a protective layer on the material not less than 0.15 mm.

The choice for this age is best done in favor of natural or PVC linoleum. If this is the second option, then pay attention to its basis. It should be made of padding polyester, felt or foam material.

Choose the material carefully if you plan to make a “warm floor” in the nursery.

From 3 to 10 years

Synthetic fibers with printed print are usually used for a boy or girl aged 3 to 10 years. The thickness is chosen of the order of 3 mm with an additional protective layer of 0.2 mm.

Children at this age love to spend time on the floor, so the insulating material should be used as the substrate.

From 11 to 16 years

Children from 11 to 16 years old become less mobile. Home games on the floor are replaced by other interests. The print is changing: now you need to add adult notes and a neutral color.

For this age, the recommended coating thickness should be at least 1.5 mm, and the additional protective layer should be at least 0.2 mm.

To determine the quality of the goods, we picked up a number of criteria. Tips for choosing will fall by the way to newcomers in such an important matter as choosing flooring for a child’s room.

Consider the following nuances:

- Width of the goods provided. Before you buy, make measurements facing surface. The material must be purchased with a margin, as it is possible the discrepancy of the surface with the room geometry.

- Smell. Natural linen has the aroma of flax oil. If you feel an unpleasant and sharp smell, then such products are of poor quality, or the technology of its production has not been properly observed. It should be abandoned.

- Appearance. Gloss should not be too strong. Drawing on the canvas should be different clarity.On the poor quality of the goods say swellings, creases or bubbles. From the butt should be visible emerging layers.

- Strength. The product must be durable so that it can withstand mechanical stress and stress.

- Surface. Linoleum should differ smooth, but not sliding surface.

- Manufacturer. Brand products with an unsurpassed reputation are always used in the production and storage of the necessary rules and regulations.

- Certificate. Require this document from the seller - its presence indicates good product quality.

- Marking. Pay attention to the packaging: there is all the necessary information.

- Purchased goods should not be stored in several layers: torsion in a roll - this is its proper storage. Bends strongly spoil the surface.

- Fixing tape should not be made from the front surface - residual effects from the adhesive structure will be difficult to remove.

Installation recommendations

An important point is also laying flooring.

Below are some guidelines for this process.

- The material is best laid on the base of plywood or OSB. For complete comfort under the base can also be laid insulating layer.

- The substrate can not be done if the base layer of the material has a rather thick structure (felt or expanded polyvinyl chloride). The remaining options should include laying on the base of the roll tube.

- Installation should only take place using the adhesive composition recommended by the manufacturer of linoleum. It must have a natural composition and not react with the bottom layer of the floor covering.

- It is strongly recommended that after the work performed, to air the room where the work was carried out for at least one day. And the introduction of the child in the room should be made not less than a week.

Video, how to lay a linoleum with your own hands, can be viewed below.

Operation Tips

In order for your flooring to remain the same throughout its lifetime, you need to use a number of floor care recommendations.

What not to do

- This coating is afraid of hot water. If you make with this frequent cleaning, then on the upper layer is formed "bald spots".

- Open access from direct sunlight can also damage linoleum - it will fade.

- The material laid on the balcony from exposure to cold will become unusable. Cracks and deformation will appear on it.

- Abundant water wetting will damage the PVC coating.

- Rubbing the surface with abrasives and a metal sponge will scratch and leave marks.

- Sharp objects - heels, furniture legs, knives or forks - will leave their mark on the laid PVC linoleum.

- The use of bleach will damage the coating due to its chlorinated composition - stains will appear and the color will fade. In this case, it is recommended to dilute the concentrate with water.

There is some protection of the surface of linoleum from various threats: fluids, damage, ultraviolet radiation and traces of shoes. It is necessary to apply polymeric mastic or polish on the surface. The resulting film and protects against all these adversities.

For the correct application of protection, it must be done in two layers and leave the material for 8-10 hours, while not loading it.

In order to prevent scratches or cracks on the surface, it is necessary to apply linseed oil or linseed oil on the surface. Such an operation is worth doing 1-2 times a month.

Reviews

Of the majority of manufacturers, the following popular linoleum brands stand out, which you can learn from reviews from parents and just buyers:

- Forbo Flooring Sistems. Differs in high-quality products, but the installation requires a highly skilled master.

- LG Haysis. Linoleum of such a manufacturer is easy to maintain, does not fade, has a rather low price.

- Tarkett. This is a domestic manufacturer.Its products have features including: the appearance of an unpleasant smell and pink color; it loses its original appearance. But parents acquire this material because of its original style and excellent imitation of wood. Suitable for a room for children of different ages or different sexes.

Examples in the interior of the nursery

There are many examples in the interior of the nursery, here are some of them.

The linoleum imitating wooden structure perfectly fitted into the interior of the room for the girl.

The covering of the children's room for the boy continues the general theme of the interior in bright colors.

The beige color of the flooring is in harmony with the calm shades of the children's room.