Kids swing with their own hands

In order to have a little rest from everyday life in a quiet and cozy atmosphere, as well as to make your children enjoyable, we suggest you to build a swing with your own hands. After all, they not only play the role of an element of rest, but also have a positive effect on family relationships.

Kinds

All swings can be classified by the number of axes of rotation:

- With one axis of rotation. Such swings are simple in execution and are the easiest option. The movement of the seat is exclusively back and forth perpendicular to the beam on which the structure is placed. The minimum height from the ground to the seat in this case is 35 cm.

- With multiple axes of rotation. In this case, the movement of the seat is added from the side to the side. This design is quite laborious. Suitable for older children. The distance from the seat to the ground is the same - 35 cm.

- With one point of suspension. The elements with the help of which the swing moves, this is a chain or a rope, converge at one point under the crossbar. In this case, the distance from the ground to the seat and from the seat to the supports of the structure will be 40 cm.

They are also divided by purpose:

- Mobile. This version of the game has a simple non-heavy construction, making it easy to move it from one place to another. For example, in any convenient place for the game: even to the house, even to the street in the shade.

- Family. Have a huge heavy construction. At first glance, it is a bench without support elements with a large back. On such a swing, the whole family can fit. For its attachment, a U-shaped construction is used, and as a fixation, chains or cables differing in excellent strength. This type of game construction can be covered with an awning or to build a roof over it - and roll even under the rain.

- Baby. This category of swing is made in the form of boats or suspended chairs. Boys will only be able to ride them when adults are near their seatbelts.

Differentiation by the type of construct:

- Hammock Fastening occurs with the help of a metal crossbar. It can, of course, be exchanged for a solid lower branch of a tree, provided that it is fairly straight. Weight, which is able to withstand the hammock design, is about two hundred kilograms. When using this construct, you can feel the flight above the ground. This option is very popular with fans to read books.

- Single. Have a various design. Do not need to install additional bar. Feature - ease of installation, so this type of swing can be installed anywhere. Different materials are used for the construction.

- Sun beds. This system accommodates three people: one child and two adults. The configuration of the swing is such that its fixation is necessary only at one point, so it can be installed in the apartment. The strength of such a product, despite its apparent lightness, is rather high due to the metal alloy.

- Suspended. Constructive this version of the swing is usually done from the seat and a few cables or sturdy chains. Fastening of cable elements occurs from each side. The sizes of such a product are diverse: they depend on the materials used. Distinctive qualities of a design are durability, ease and comfort.

Required Tools

Before you start making a swing, you must first prepare the required tools and materials. So, what we need:

- File and sandpaper for metal.

- Welding installation.

- Electrodes.

- Container for the preparation of the solution.

- Components for the manufacture of mortar - crushed stone, water, cement, sand.

- Fasteners - bolts, nuts.

- Pipes from metal.

- Wrenches.

- Shovel.

- Grinder with discs on a metal surface.

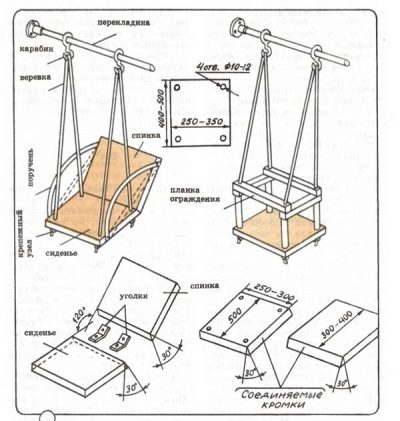

Preparing drawings

After all the preparatory moments are completed, it is necessary to translate the idea on paper. To do this, you need to understand what kind of swing design we will do.

Having defined the constructive and type of swing, mentally imagine them awake as if you were already swinging on them. And now it's time to draw them. After completing the sketch, we recommend to look for similar options on the Internet. After all, the drawings can be both unique and those for which work has already been completed. It’s better not to reinvent the wheel, but to take ready-made options - this will save you time and energy.

Below are several options for drawings, with which you can independently perform the construction in the form of a swing for children.

How to make a street swing

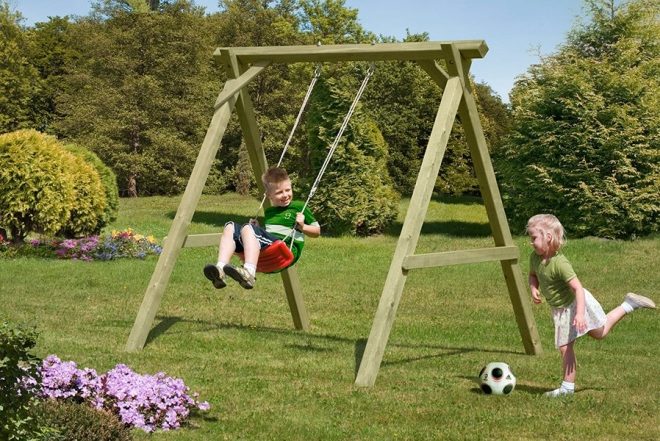

From wood

For the manufacture of wooden swinging elements will need the following material:

- Glued laminated timber 8x8 or 10x10 cm.

- Plywood is thicker.

- Solid wood

- Boards.

- Chains, nuts, bolts, screws, screws, studs.

Manufacturing process:

- Using a drill, we dig 2 pits 1-1.5 in depth and 20 cm in diameter.

- We make cases of fossa of ruberoid.

- We throw the remains of bricks or large stones into the pits and fill with concrete.

- As soon as the concrete grasps, we mount the corners of metal to install the supports.

- The aboveground component of the concrete base should be polished and painted in a bright shade.

- Tighten the base with screws (120 mm). To do this, first make a cut in the bar and set the studs. Using a hacksaw, we cut out the struts and fasten them to the structure with the help of studs.

- Using screws, we make the seat of thick plywood. We varnish and fasten the sides of the chain.

- We make cuts in pillars and install them on mounted corners.

- Suspend the seat.

How to make a wooden swing with your own hands, you can learn from the following video.

Swing made of wood ready.

Of metal

Here we will explain how to perform a metal swing on the bearings with your own hands.

In order to lay the pillars we need:

- 74th metal pipe - 2 pcs.

- Bearings - 2 pcs.

- 15th pipe - 1 pc.

- Cement mortar.

- Shovel.

- Sand.

- Welding machine.

- Iron strip 7cm - 1pc.

The process of installing supports:

- In the thick pipes make special holes on top. It is necessary that they lay the crossbar.

- Cooking cement mortar.

- We dig holes for support.

- We dig in pillars and concretes.

- On the crossbar install 2 bearings with limiters of steel strip. They must be welded to limit the movement of the bearings from side to side.

- Install the crossbar on the support. It is also welded.

The list of necessary materials and tools for organizing seating for a new swing:Welding machine.

- Hammer.

- Screwdriver.

- Angle grinder.

- Pipe bender

- Roulette.

- 32nd pipe - 8m.

- Chain - 6m.

- Board 314x25 cm

- A strip of steel with a length of 341 cm.

- Carabiner for chains - 2 pcs.

- Bolts for carbines - 2 pcs.

- The coloring structure and water-repellent liquid.

- Small screws - 42 pcs.

Seat fabrication process:

- Bend the pipes as necessary and boil with a welding machine frame.

- We process the wooden surface with water-repellent liquid and paint it with ordinary street paint.

- We put a wooden surface into the frame and fasten it so that it fits tightly. This can be done with a metal strip, welding it in several places behind the seat: on the sides and horizontally along the seat.

- Chains with snap hooks are bolted.

- Bearings and chains are also bolted through iron bars specially bent with a hammer for this business. The size of the strips is about 20 cm.

Now you can use the swing.

Suspended

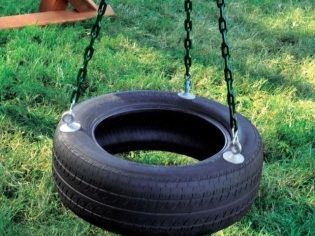

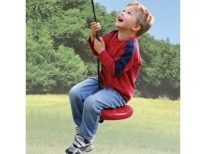

The configuration of such a swing can be varied. Here are a few of them:

- Bungee - the simplest design. It is made of rope tied at both ends. Above there should be a solid crossbar, and from the bottom - a plate or a round crossbar.

- Tire Swing - a variant similar to the previous one. They are suspended both in vertical position and in horizontal position. You can create fancy shapes from them, which gives an impetus to the creative process of creating a unique swing design.

- Another option is a plate or piece of tarpaulin is suspended from both sides of the edges symmetrically on two ropes or chains.

- With wide seats. This option is usually attached with four ropes or chains. Instead of wide sitting, you can use old chairs without legs, pallets and even benches.

- Soft swing. Its design resembles a hammock. They can also be made of a fabric base and wooden sticks or woven from a rope.

One of the options for a swing swing will be discussed in the next section of this article.

On the spring

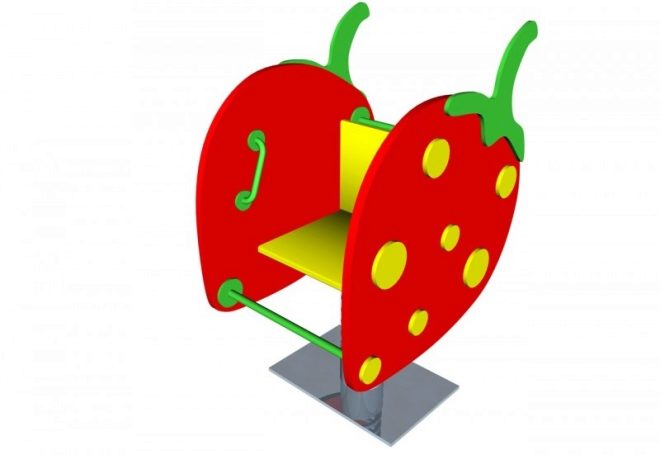

This kind of children's entertainment can be set to cottage - children will love it.

Manufacturing process:

- We purchase a truck spring at a metal market with a height of at least 35 cm - this will be our spring.

- We dig a hole under our spring.

- We assemble an anchor: for this we need a crosspiece (reinforcement with a diameter of 20 mm can be used) and a pipe 50-60 cm long. These two elements must be welded.

- Fastened with a lug anchor and spring.

- We lower the anchor into the pit, level it and fill it with concrete.

- Weld boss to the spring. This is necessary for fixing the body of the swing.

- We take a drawing paper and draw the necessary configuration of the case - it all depends on your imagination. Do not forget about the handles for which the baby will hold in the process of riding.

- We transfer the drawing to plywood and cut it out with a jigsaw.

- Fasten the housing to the boss with metal strips of dimensions 30x4 mm and bolts.

- We color the swing in bright colors.

You can also find out more on how to make a swing on a spring with your own hands from the video below.

Now you can use the swing.

We do for home and apartment

Any homemade design that is used at home by children must meet certain safety requirements. This also applies to swing, made with his own hands.

Requirements:

- Material. It must be environmentally friendly. It is advisable to use natural materials. For example, a perfect tree. And in homemade The setting is also a good microclimate that will positively affect the health of your children.

- Order. After the child rode on the swing, they should be removed. Stay close to him while skiing.

- Elements of the swing should not be traumatic. Hands and feet should not be confused and stuck in them.

- Workmanship. The entire surface of the swing should be smooth - polish it in the best way and free from knots.

Before proceeding to manufacture, you need to determine the space where the swings will be, and prepare all the necessary materials for this.

The materials that we need for the manufacture of devices for skiing:

- Plywood (board) with dimensions of 400x400 mm for the manufacture of seats.

- Limiting strips with dimensions 400x65x20 mm 5 pcs.

- Copper tubes 4 pcs. with a diameter of 20 mm: two 65 mm long and 2 125 mm long.

- 6 m long rope

Manufacturing process:

- The board for sitting and levels needs previously to be processed by a plane. Sharp and protruding parts need to be removed.

- We drill holes in the 4 corners of the seat at a distance of 40 mm from the edges. The diameter of the holes should be 6-10 mm.The limiter plates also need to be drilled with the same distance to the edges. Recall that there are only 5: 2 go back, 2 - on the sidewalls and 1 - in front.

- We assemble the entire structure. To do this, push the rope through all the holes and fix it with secure knots.

- We hang the swing and paint.

Swings for home ready.

Child safety rules

Below are a few rules by which your child will be safe when riding:

- If the swing design implies a single point of suspension, then the fastening of its elements must be made in such a way that the rope or chain does not twist during the swing.

- If a chain is used as a suspension, then it should be sheathed. Unwanted garden hoses can help. This is necessary so that the fingers of the child do not fall into the chain.

- Placing two swinging devices on the frame is not allowed. In this case, the possible collision of children with swinging.

- Secure the landing area. Sliced bark or sand will soften the blows at possible falls.

- Make the seat light. For this fit plastic, rubber or wood.

- The seat must be different springy qualities. Bumpers, broken off by rubber - quite an acceptable option. This should keep children from being hit by a swing.

- At the perimeter of the landing zone there should be no plants that could harm the child.

- All wooden components carefully process a plane, polish and apply varnish on them. So children will be warned against spills and scratches.

- All the protruding parts in the form of bolts and nails, as well as other metal parts, drive into the wood.

- From the safer designs of the swing, L- and A-shapes are distinguished. This is due to the fact that in this case the load is less on the structure than with other forms. The greater the distance between the vertical supports, the more reliable the construction is and the less wear and tear on the parts during use of the swing.

- Carabines of a swing swing tend to wear out quickly - they need to be changed once a year. Use carbines with plastic inserts, so they will be protected from wear.

- Do not use hooks instead of carbines. In the process of active swinging, they can break, and the child will suffer.

- It is better to lubricate the place where the rope and attachment point contact with engine oil. From this, its service life will increase.

- The arrangement of children's swing options must meet safety requirements. It must be places outside of any vertical barriers: walls, fences, trees and all kinds of buildings. With a strong swing, there is a high probability of injury to the child. In addition, inspect the nearby area for the presence of sharp and cutting elements - they should not be.